UV curing systems that dry in seconds eliminate pre-paint wait times and inconsistencies in primer application to increase collision repair shop capacity, quality and profitability

Ask an automotive collision repair shop owner about how to increase productivity and chances are you will hear about the need to reduce pre-paint wait times. Each laborious step can add hours of drying time to the repair timeline, limiting how many vehicles the shop can repair. The opportunity cost in terms of lost revenue and profitability is significant.

Now, however, advanced UV technology is taking the waiting out of the process and delivering near-instant curing of all three pre-paint steps: body filler, glazing and priming. By doing so, auto collision shops can process more vehicles each week.

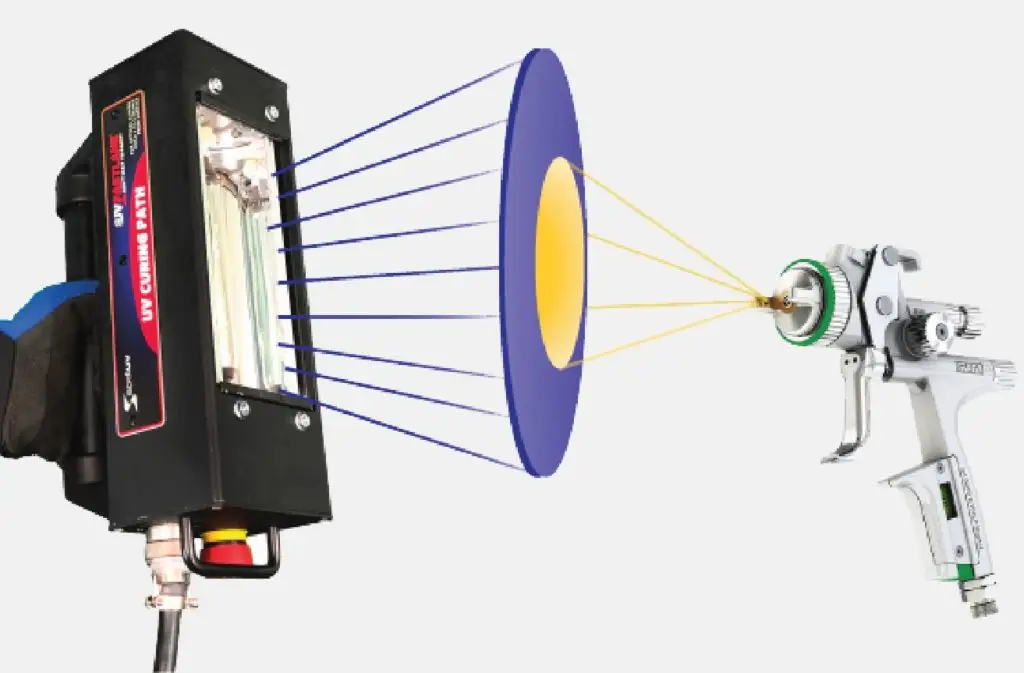

Unlike the less efficient UV curing lighting stands of the past decade, the new technology involves powerful handheld UV devices that cover larger areas and cure within seconds. The time saved with near-instant UV curing directly translates to increased vehicle capacity.

Without having to expand a collision repair shop at a cost of up to $150,000 for an additional bay, operators can leverage the latest UV curing technology to increase the number of cars they repair by up to 50%. With the UV Fastlane patented system from SPDI UV, an operator waves a mobile wand over the repair surface, just as they would to spray paint.

The body filler, glaze or primer dries within seconds. The wand delivers 2400 watts of curing power to a depth of up to 12 Mil on a single pass based on a high intensity irradiator.

For more information on SPDI UV and their UV curing technologies, visit their website at uvfastlane.com or call 1-844.258.7457.