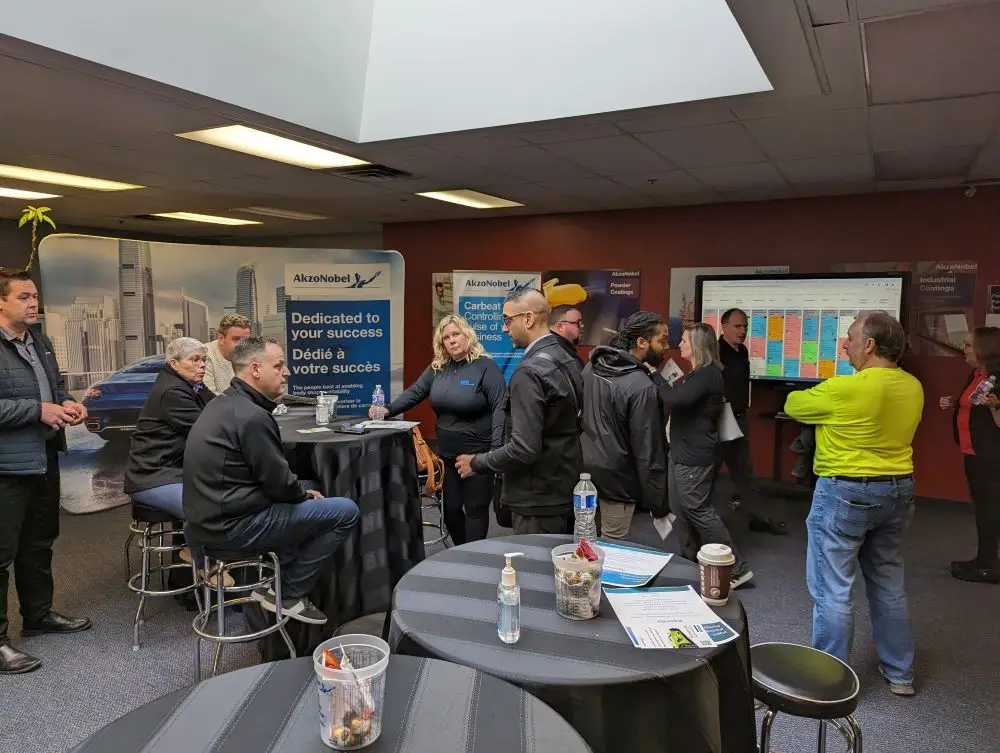

The event showcased collision repair innovations, the adaptation to new vehicle technologies, and the importance of nurturing skilled talent.

In February, AkzoNobel hosted an Open House event at their Ontario headquarters in Etobicoke, offering attendees a glimpse into the present and future of collision repair through latest developments in coatings, technology, and processes. The event also featured the unveiling of the new Automated Dosing Machine, Santint AC100. Collision Quarterly had the privilege to be onsite to explore the AkzoNobel’s training centre and participate in a series of engaging demonstrations and discussions.

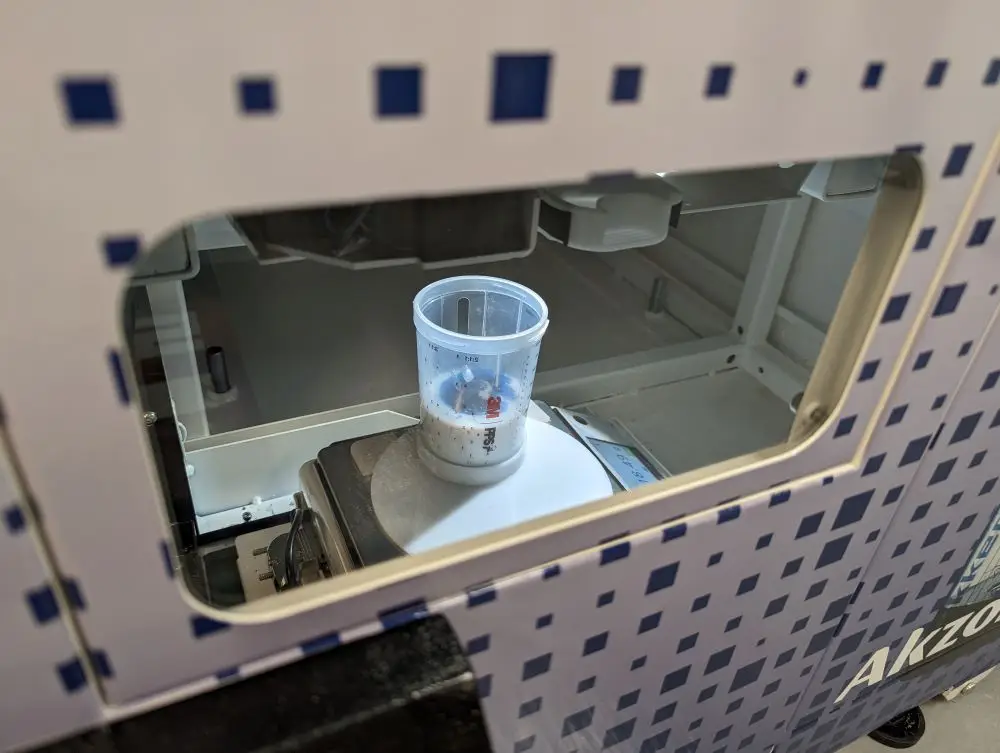

AkzoNobel’s Automated Dosing Machine

A highlight of the event was the demonstration of AkzoNobel’s Automated Dosing Machine, designed to enhance the efficiency of high-volume collision centres. Technical Consultant, Dave Woolley, showcased its ability to mix 200 grams of paint in just 4.32 seconds, which marks a notable advancement in streamlining paint processes. Wooley emphasized that the machine’s potential is to free up skilled technicians for other tasks, potentially adding thousands of dollars in daily revenue by increasing booth cycle turnover. “The booth cycle is about two hours. If I can get one more cycle through that booth a day, that might translate into thousands of dollars more in revenue every day,” said Woolley.

The machine simplifies the mixing process to the extent that it does not require any technical painting training to operate, allowing anybody in the collision repair centre to accurately and consistently mix automotive paint finishes.

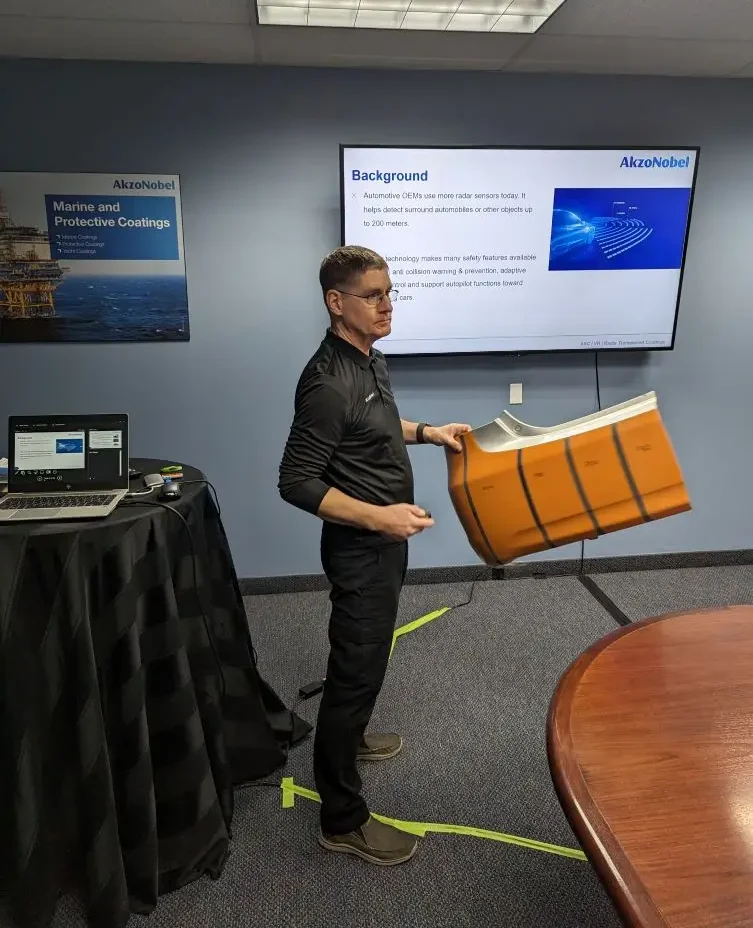

ADAS Challenges with Appropriate Coatings

Another critical discussion centred around the importance of choosing the right coatings for vehicles equipped with Advanced Driver-Assistance Systems (ADAS), such as radar and sensors. These critical safety technologies, which support functions such as collision warnings and adaptive cruise control, demand meticulous refinishing practices to preserve their operational effectiveness. Brad Kruhlak, technical manager at AkzoNobel Automotive & Specialty Coatings, underlined the importance of adhering to vehicle manufacturer-specific repair guidelines to prevent any compromise to sensor performance. For example, he mentioned that Honda provides specific paper templates for technicians to use during bumper repairs involving radar sensors.

Kruhlak pointed out the challenge posed by certain coatings that can either weaken or reflect radar signals. This issue is particularly relevant as 60% of automotive paint formulas include metallic components. To address this concern and ensure seamless compatibility with ADAS technologies, companies like AkzoNobel are developing specialized products that maintain sensor functionality without interference.

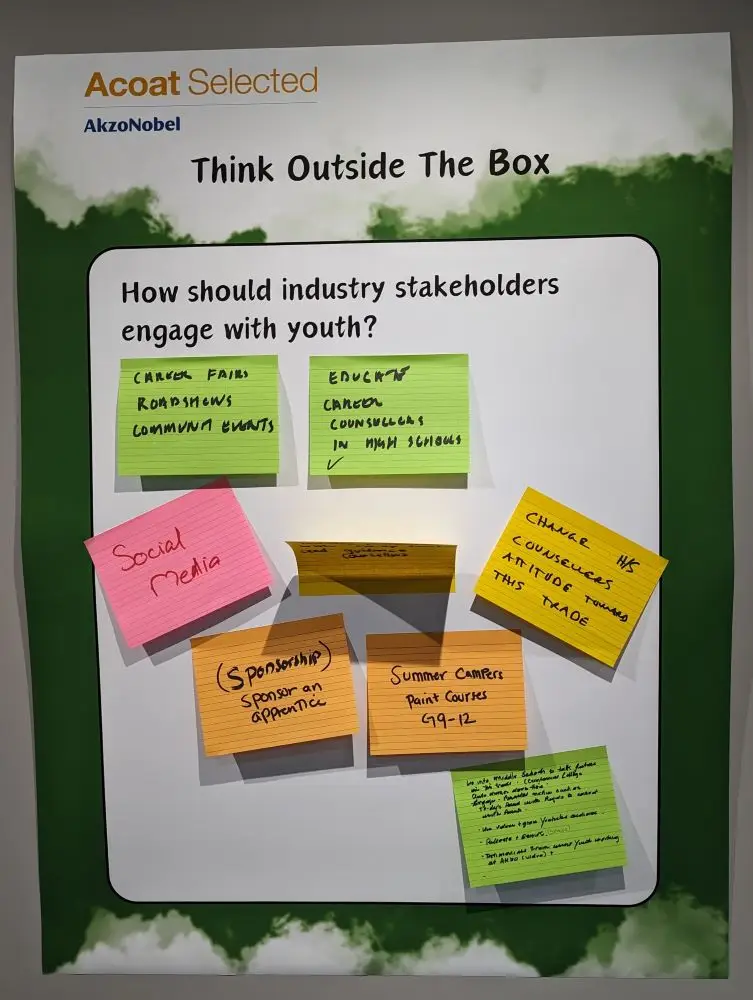

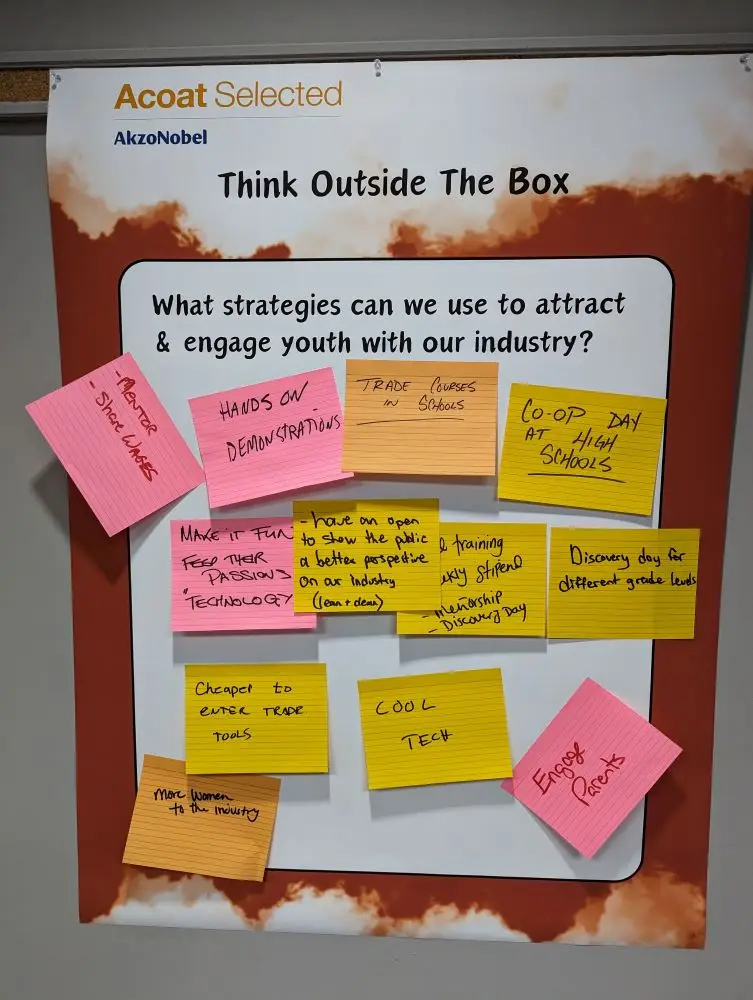

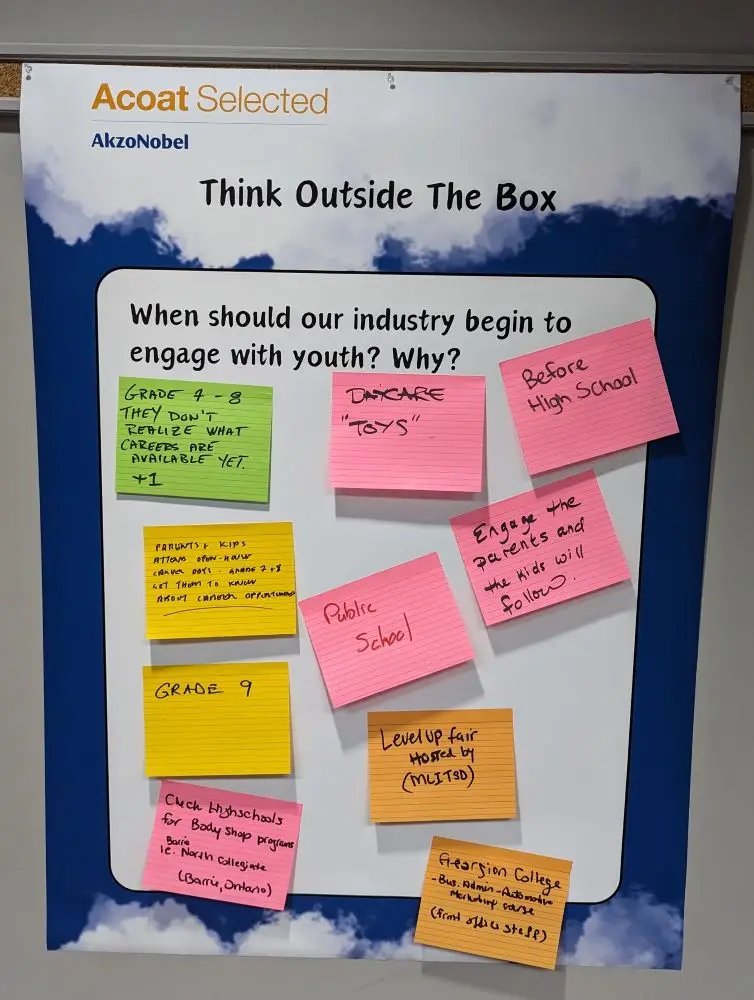

Engaging Youth in Collision Repair

Addressing the industry’s urgent need for young talent, the event sparked discussions about methods to engage, attract, and retain young professionals. Attendees were encouraged to share their thoughts on improving recruitment and training practices, with each suggestion being noted on sticky notes for a visual representation of the collective brainstorming. The conversation underscored the significance of creating awareness, extending support, and offering mentorship as essential approaches to cultivate and integrate the upcoming workforce into the industry.

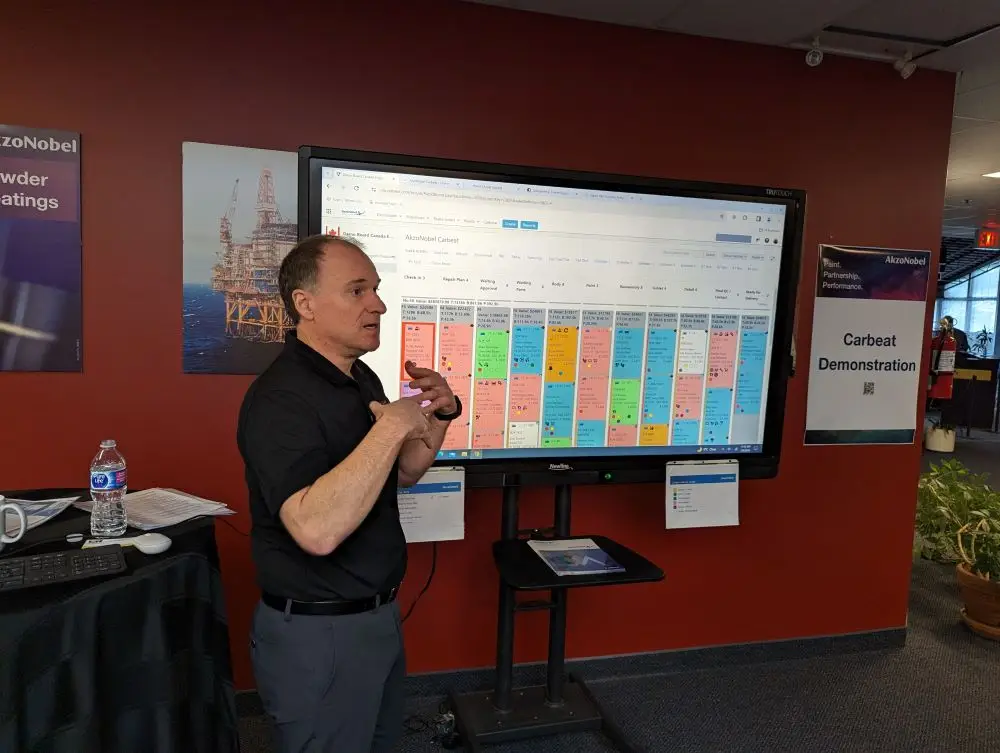

Streamlining Operations with Carbeat

John Cox, services manager at AkzoNobel, showcased the features and benefits of Carbeat, AkzoNobel’s digital process control solution. Cox’s demonstration highlighted how Carbeat helps boost communication and production efficiency in collision repair centers by integrating data across various elements such as cars, activities, parts, materials, and information flows. This integration demonstrates Carbeat’s practical role in modernizing shop operations.

As a visual tool, Carbeat enables users to quickly and effortlessly navigate through the system, providing immediate access to real-time status information of repairs, thus streamlining workflow in the shop. It efficiently links all necessary data to ensure smooth operations, making it an invaluable resource for front-office staff, repair technicians, planners, and shop management.